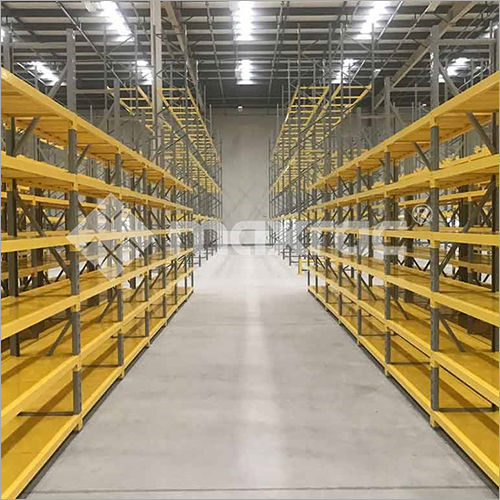

Radio Shuttle Racking System

1.50 USD ($)/Kilograms

Product Details:

X

Radio Shuttle Racking System Price And Quantity

- 4600000 Kilograms

- 1.50 USD ($)/Kilograms

Radio Shuttle Racking System Trade Information

- Shanghai Port,China

- 5000 Kilograms Per Month

- 20-30 Days

- Yes

- Contact us for information regarding our sample policy

- Export Standard Package

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

- CE, ISO9001

Product Description

Enter Buying Requirement Details

Other Products in 'Storage Shelving' category

Our major exporters countries: Europe, Southeast Asia, Australia, North America, Middle-East

|

SHANGHAI SPEED LOGISTICS EQUIPMENT CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Call Me Free

Call Me Free